I believe

Morgan Yachts outfitted the M382’s with the house and starter batteries under

the quarterberth on the starboard side of the vessel. Here is and image of what we found aboard

Pilgrim when she arrived in Beaufort, NC in late January 2014.

|

| House battery bank (green) & Starter battery (blue) when we took ownership of Pilgirm |

One of our

initial projects was to clean up the residual mess and damage in the battery

compartment.

|

| Removing wood cabinetry damaged by battery acid spill. |

During this clean up we decided to re-locate the batteries. Nearly 21

months later we can finally say the we are finished with the effort.

We removed a

drawer and storage locker from below the salon seat forward of the galley

sinks.

|

| The salon seat forward of the galley sinks - site of the future house battery bannk. |

We

fabricated and installed a battery box capable of storing six 6V

batteries. This will be Pilgrim’s new

house bank.

|

| House bank install complete. |

|

| Two removable panels conceal the battery bank. |

|

| Battery bank closed. We installed vents on the forward and starboard sides of the cabinetry. |

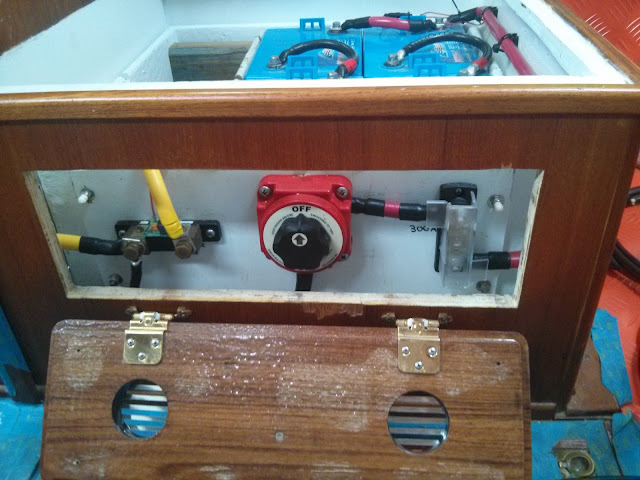

We used the

opening and the door face from the original drawer to create access to the

battery monitor shunt, battery switch, and ANL Fuse.

|

| Hinged access to shunt, battery switch, and ANL fuse. |

Back at the

quarterberth, we removed the deck and gutted the original dividers.

|

| Deck and dividers removed from quarterberth. |

We tabbed

new dividers to the hull and created four new lockers… two outboard for

storage; inboard and aft for the engine raw water thru hull and strainer,

inboard and forward for the starter battery.

|

| New dividers and deck in quaterberth. |

In addition

to the start battery the inboard forward compartment also houses the automatic

charging relay, bilge pump switches, and the battery control panel.

|

| Looking down into locker containing ACR, Start Battery, & wiring for bilge pumps and battery control panel. |

The battery

and bilge pump panel is located below the navigation station bench seat. This is the site of the original battery

selector switch.

|

| Battery control & bilge pump switch panel below nav station seat. |

For

additional images and notes check out our – Battery Relocation Photo Album