Our recent

installation of Pilgrim’s primary 12V DC wiring required the numerous large

gauge, 4 to 00, electrical wires. If

you’re wondering which is the larger wire a 4 or 00, then check out our

previous post – Let’s Talk Marine Wire, October 18,

2015.

|

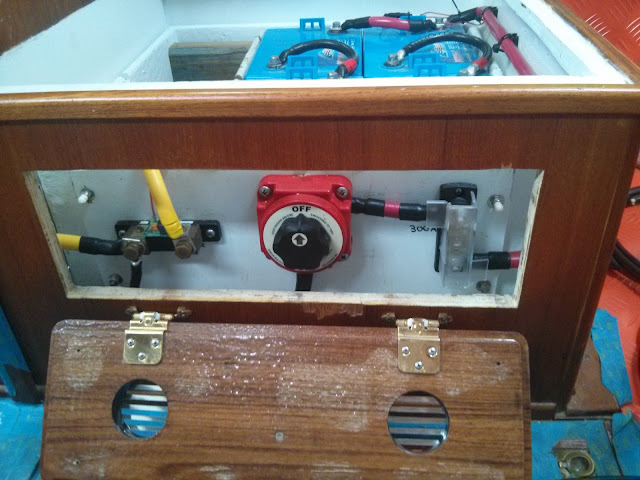

| Large gauge wire runs at electrical panel and starter battery. |

|

| Large gauge wire runs at house battery bank. |

Here are a

few things I picked up about crimping lugs onto large gauge wires.

Happiness is

having the right tools for the job at hand.

The key for installing wire terminals on large gauge wire is having the

proper crimping tool. Unfortunately

appropriately sized, quality crimpers are expensive and rarely part of the DIY

sailor’s quiver of tools. Fortunately I

am currently able to borrow a great crimping tool with dies for crimping 6ga

through 4/0ga.

If anyone

out can recommend a source for purchasing a quality pair of crimpers functional

on 6 to 2/0 wire, then please share the info in the comments.

|

| Tools and materials: Clockwise from the top - heat gun, medium duty wire cutters (blue handle), large gauge wire crimper with multiple dies, 2/0 x 5/16 post lugs, heat shrink tubing, 2/0 wire. |

Heavy duty wire cutter and a sharpie style marker are essential tools missing from the image above.

I’m not

certain if there is a technical difference between lugs and ring

terminals.

|

| 22ga to 8ga insulated ring terminals on left. 6ga to 2/0ga lugs on right. |

Ring

terminals and lugs need to be sized to the correct gauge of wire and to the

correct post diameter. In the image

below both lugs are for 2/0 wire. The

lug on the right fits a 3/8” post and the one on the left fits a ¼” post.

|

| Two 2/0ga lugs with holes for different size posts. |

Avoid

aluminum when purchasing wire connectors.

Like marine wire all terminals and lugs should be tinned copper.

I’ve found

my medium duty wire cutters will realistically work on wire up to around 1

gauge. 0 through 4/0 wire will require

large cable cutters. Sailing vessels

should be carrying large cable cutters to deal with wire rigging in the event of

a dismasting (See our C’est la Vie post: Dis-masted – Part 2 if you doubt the necessity of having

large cable cutters aboard.) Cutting 4/0

wire is easy with the large cable cutters.

Once the

wire is cut to the proper length, slide a section of heat shrink tubing for

each lug to be installed onto the wire. Sliding

the heat shrink over the wire at this point will aid in avoiding any fraying of

the wire once the insulation is removed.

Next, using the lug as a guide mark the amount of insulation to be

stripped off the end of the wire.

The medium

duty wire cutters are my tool of choice for stripping wiring larger than 10 gauge.

|

| Stripping 2/0 wire using medium sized wire cutter. |

Apply gentle

pressure to the handles while rotating the cutters around the wire. I prefer to rotate back and forth through

180 degrees. Rotating through 360 degrees is ergonomically

awkward and often results in a spiral cut on the insulation. Stop the motion when you begin to feel the strands

of copper against the edge of the cutters. Knowing when to stop cutting and how

much pressure to apply comes with practice.

Once the

insulation is gone, I move directly to installing the lug. Expediency at this step will aid in avoiding

any fraying of the small stands of copper wire.

|

| Crimping a lug on a 2/0 battery cable. |

Once the

crimping is completed, I give the lug a through visual quality inspection. If satisfied with the connection, then slide

the heat shrink tubing over the junction and let the heat gun do the rest.

|

| Numerous 2/0ga battery wires in Pilgrim's house battery bank. |

Happy

Crimping!

For large gauge wire I perfer the Quckcable Cub crimper but it only goes up to 1/0 Magna lugs. Magna lugs are much heavier than the lugs you used finding a portable crimper that does 2/0 well is hard.

ReplyDeletePierre, Thanks for the suggestion. I looked up the Quickcable Cub Crimper. Could not tell from site... does it have removable dies or how does it adjust for the size of wire.

DeleteThe expensive changeable-die crimpers are, of course, the best. I used them frequently in my career as an aircraft electrician. Unfortunately, as you said, they are prohibitively expensive. As a compromise, I purchased one similar to this several years ago. It does a reasonably good job (certainly better than vise-grips, LOL) and fits nicely in my electrical kit.

ReplyDeletehttp://www.mouser.com/ProductDetail/Molex/19294-0008/?qs=BLN8Q0P37WbS2X%252b7BTdoNg%3D%3D&gclid=CNXHguW928gCFVQkgQod3yENrg

Bob, Thanks for recommendation and the link. Via on-line searches I observed this style of crimper (Base with large pin in guide. Pin is struck with hammer to create crimp.), but have not used one personally. It is definitely less expensive and ore compact.

DeleteOn a personal note. It is good to hear from you. Hope all is well.

Google "hydraulic cable crimp tool." The yellow ones that pop up are fine for non-industrial use.

ReplyDeleteI got one from Harbor Freight and had no triuble with it rewiring Memsahib. Hydraulic feature makes it small and easy to store.

I'll be pulling it out soon for use on the new boat: www.mvtardis.com

Paul Kessinger

Paul, Thanks for the suggestion. I did find a number of compact hydraulic crimping tools on ebay and on the web. Was skeptical of their build quality. Your the second person to recommend this style. Next time I visit Harbor Freight I'l check out their stock.

DeleteThanks for sharing the link to The Tardis Project. Like the layout and style of Tardis. Somewhere in our future, after we have quenched our thirst for sailing. I envision us aboard solar/electric drive, trailerable trawler. I look forward to following your progress.

This comment has been removed by the author.

ReplyDelete