One of the

final components of re-locating the house battery bank was securing the

batteries.

Per Full River’s Specs

each 6V battery weighs in at approximately 66 pounds. Presently our house bank consists of four 6V

batteries = 264 pounds. We plan to

expand the bank to six 6V batteries = 396 pounds. Preventing this 400 pound mass from sliding

around during normal conditions is critical to the long term health of our

electrical systems. Eliminating the

possibility of this 400 pound mass from becoming a projectile in the event of a

knockdown is critical to life and limb.

We designed

the new battery box to fit snugly around the batteries. The fit will limit side to side and fore to

aft motion of the batteries.

|

| Installing the new fiberglass over plywood battery box in the space under the center salon seat. |

The new

battery box is mechanically fastened, six ¼” counter sunk, flat head screws, to

the Morgan 382’s internal glass unit (IGU).

The IGU is a structural member in the Morgan’s hull that provides strength

to the hull and a mounting surface for the cabin sole.

Since we are

two batteries shy of our desired six battery house bank, we constructed temporary

filler to prevent the existing bank from sliding fore and aft.

|

| Four 6V batteries plus the temporary filler in the new box. |

Ok, this set

up takes care of movement under normal conditions.

Next we

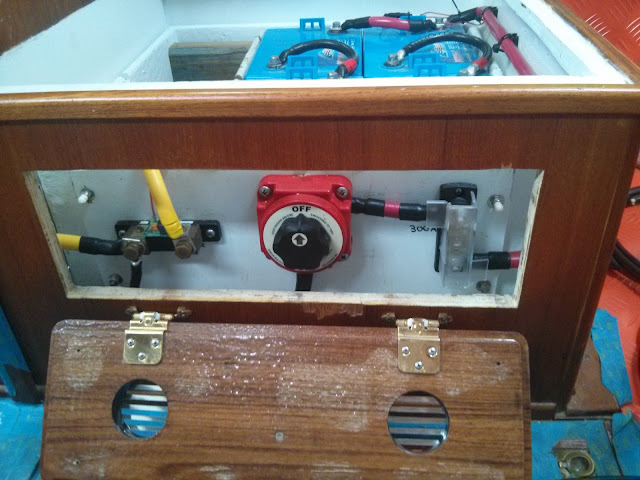

installed the system’s wiring.

|

| House battery bank wiring complete. |

We installed

the wiring to allow space for bars to run across the top of the batteries. Initially I envisioned having some stainless

steel bars fabricated to fit across the space, but custom fabrication =

$$$. In the end we decided to keep it

simple.

We purchased

two 3’ long sticks of ½” diameter stainless steel all thread rod. 3’ was more

than enough length to span the distance across the top of the battery box and

thru both adjacent 3/4" plywood walls.

|

| Using the 1/2" all thread rod to locate the hole on bulkhead aft of the battery box. |

We began by

drilling a ½” diameter hole in the plywood wall forward of the battery

bank. Running the rod through the hole and

across the top of the battery bank aided in locating the position for the hole on the wall aft

of the battery bank.

|

| We sheathed the rods in 5/8" id hose. |

When re-installing the rods, we sheathed them

in 5/8” id hose to prevent chafe or the possibility of a loose wire shorting

out to the steel rod.

The ends of

the rods are secured with nuts on both ends.

|

| Nuts and washers installed on the ends of the rods under the galley sink (center, right below black water pump). |

|

| Nuts and washers installed on forward face, below the center salon seat. |

We are

confident the batteries are secure. The next

and final step in our battery re-location project is to fabricate a lid

for the new house bank installation.

Please check

out our Battery Re-location Photo Album for additional images and notes on this

project.